Jiangxi Xinyuan New Material Technology Co., Ltd., established on November 3, 2021, is located in the Global Technology Park of Lichuan County, Fuzhou City, Jiangxi Province. It is a comprehensive enterprise integrating research and development, production, and marketing, mainly focusing on the production of disinfection equipment and diamond electrode modules. Nature endows us with the most precious water resources, and here, we use technology to make water more miraculous. Welcome to our factory and witness the magnificent transformation of water.

The diamond electrode new material developed by the company is a comprehensive ultimate material. When electrified, it can electrolyze water to produce superoxide and hydrogen gas, triggering marvelous changes. Through this process, ordinary water turns into activated water rich in superoxide. In these tiny bubbles, there is powerful cleaning and disinfection capability. This superoxide water can rapidly destroy the cell walls of bacteria and viruses, leaving no dead ends, and eliminating harmful bacteria from the molecular level, achieving comprehensive disinfection. According to reliable data statistics, the disinfection ability of superoxide water is more than 20 times that of alcohol, ensuring your safety. Moreover, superoxide water will completely return to ordinary water after 28 minutes, leaving no chemical residue. Safe, efficient, and environmentally friendly – these are the reasons we choose superoxide water.

Superoxide water makes our lives healthier. In the medical field, it safeguards the safety of every patient; in the industrial field, its efficient cleaning ability is also highly favored. From personal care to home environments, from public health to medical environments, at every step, we pour our pursuit of purity and safety.

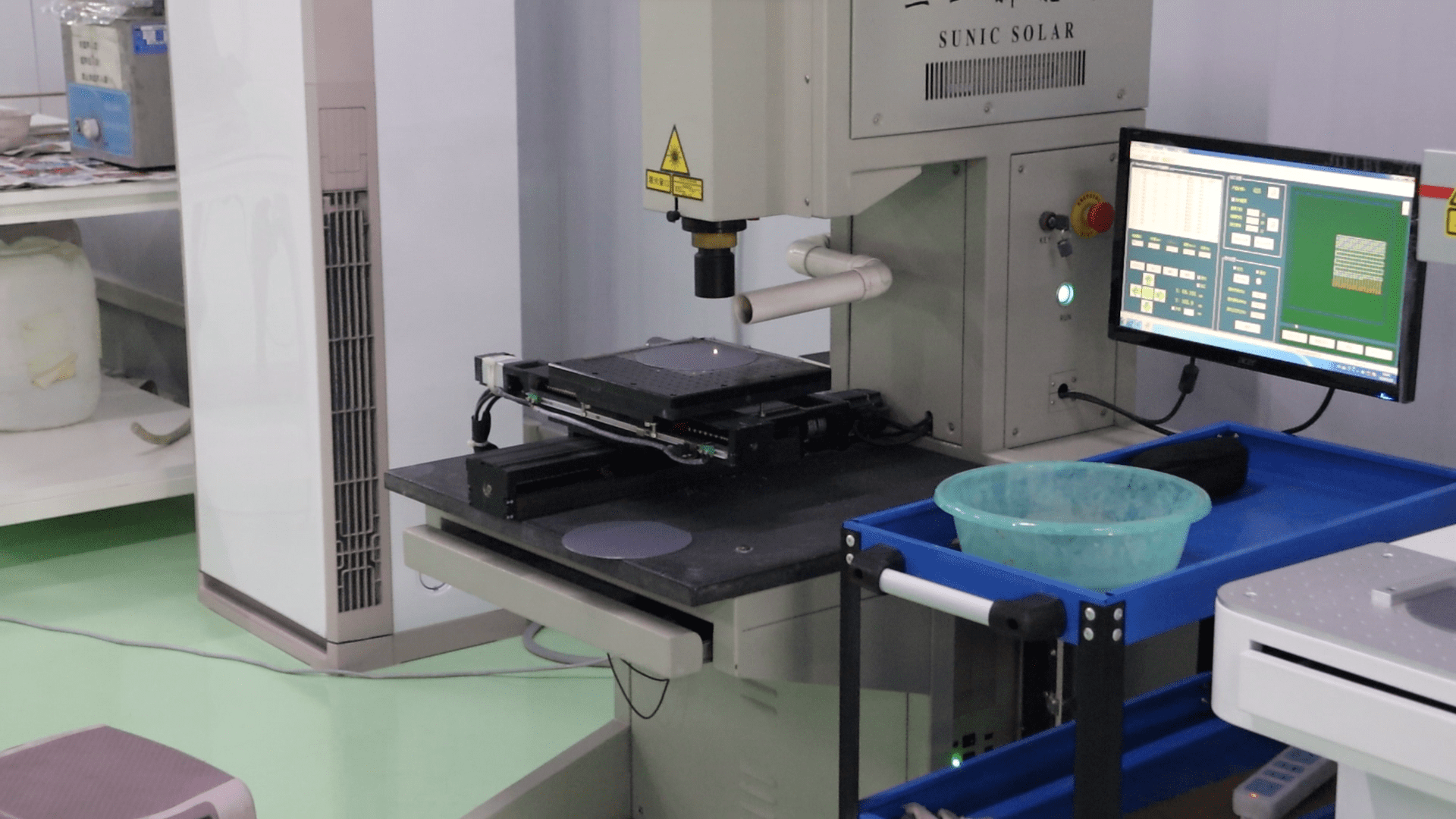

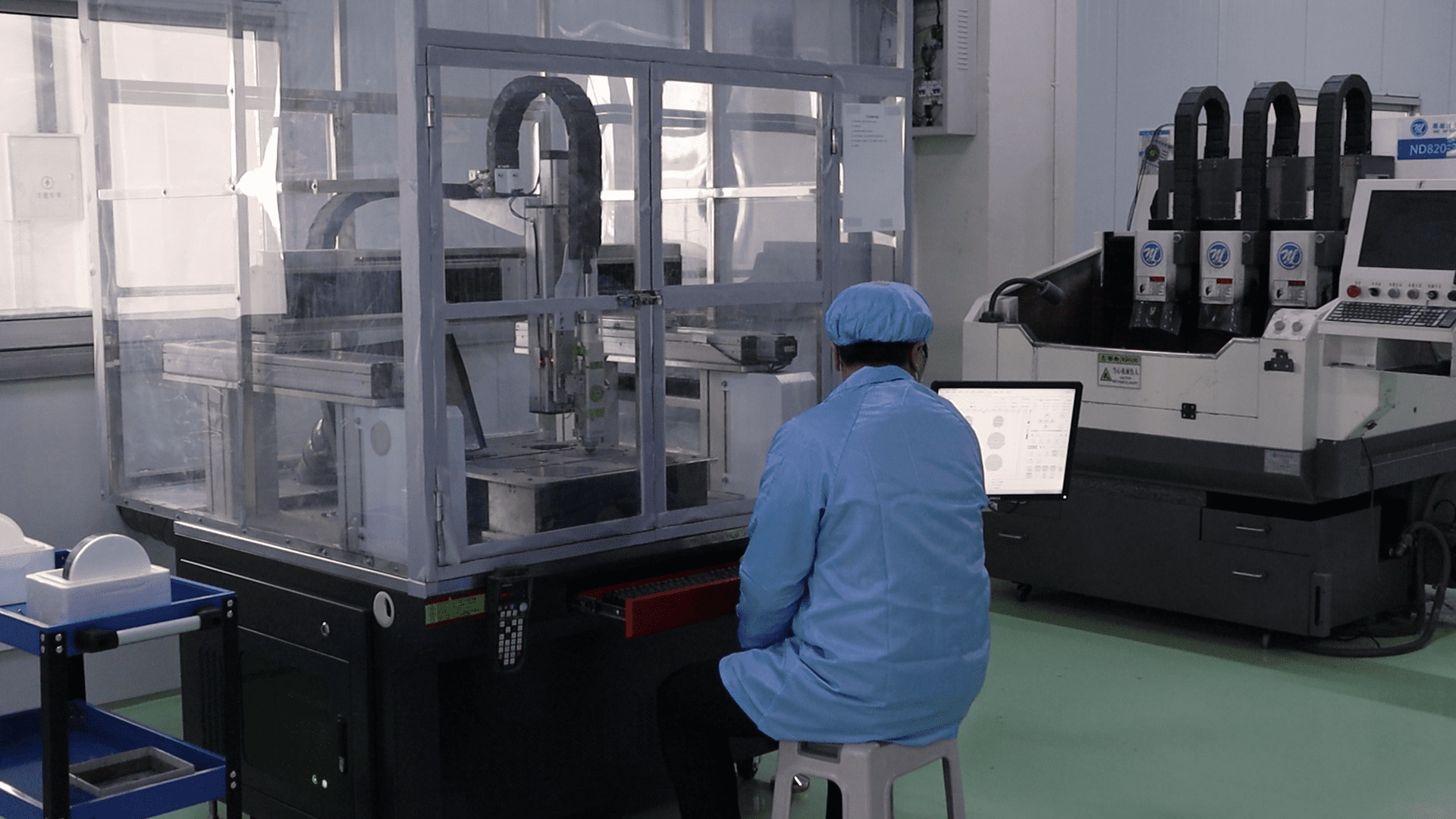

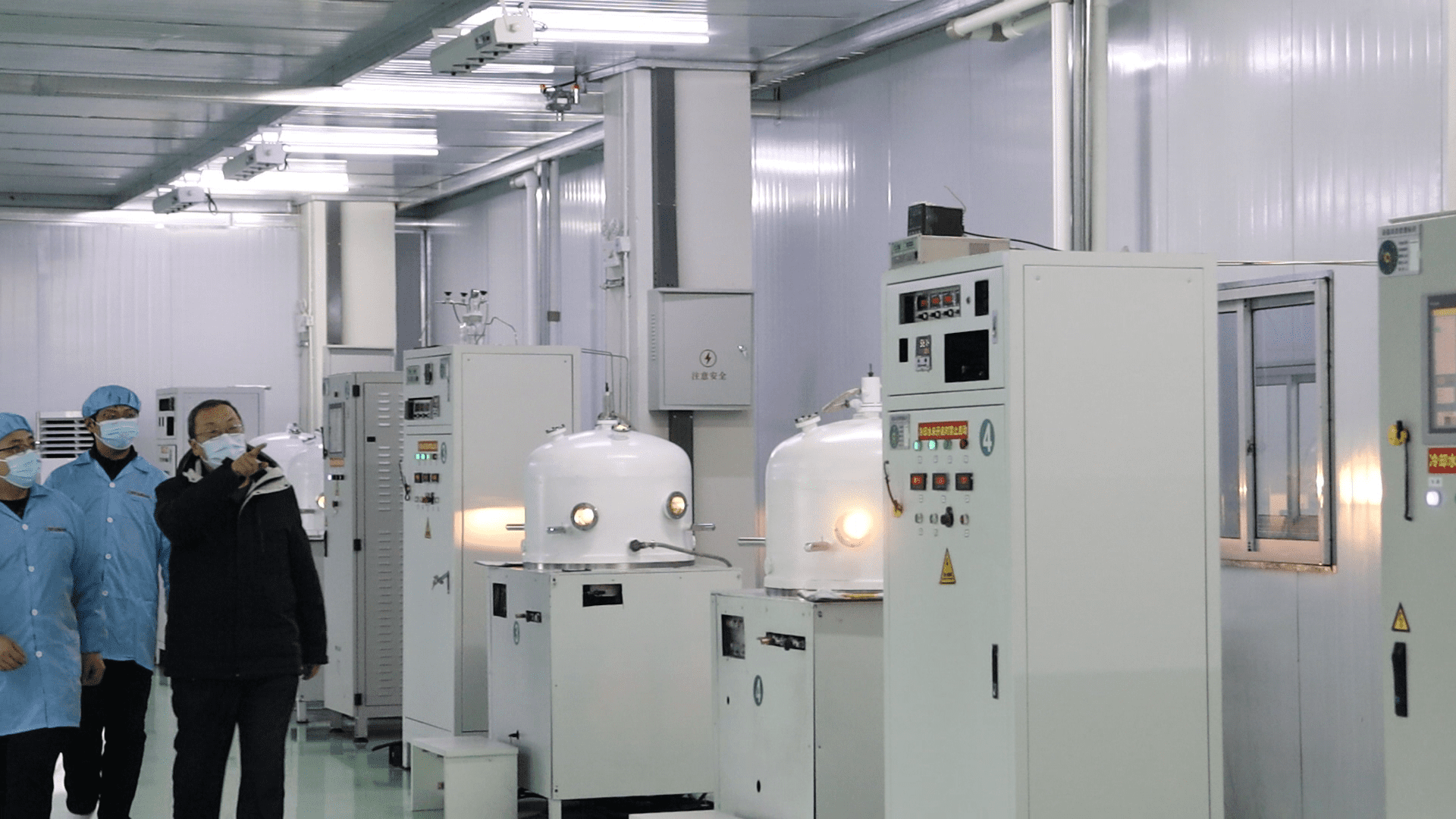

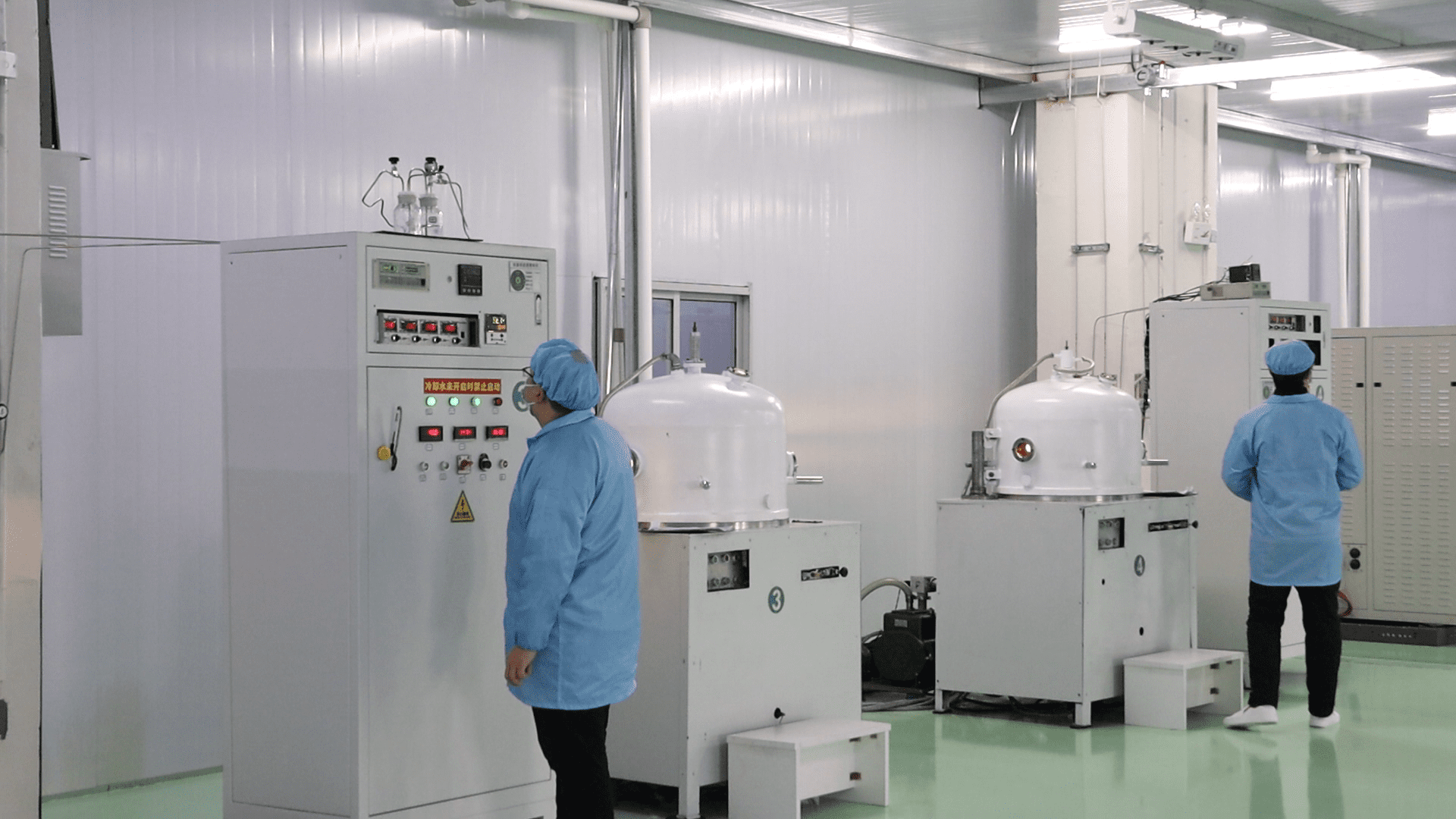

The company's factory covers a total area of 100,000 square meters, with first-class internal environment, equipped with advanced production equipment and research laboratories. We have 30 domestically produced laser deposition furnaces, 60 CNC engraving machines, 5 laser cutting machines, and other advanced equipment, capable of providing an annual production capacity of over 30 million diamond film electrode substrates and components.

The company has established a pioneering team focusing on the research and application of diamond electrode new materials, ensuring the company's continuous development in terms of technological level and product innovation. They continue to explore, providing a solid foundation for the company's development and product quality.

The company has always led the development direction in the industry, and our products have been widely recognized by customers and partners. We continuously participate in the exchange of advanced technologies and concepts in the industry at home and abroad, driving the development of the industry. Here, we not only manufacture products but also are committed to creating a purer future. Choosing us means choosing a safe, healthy, and environmentally friendly lifestyle. Let's create a better tomorrow together – we are always on the road!